Akrylika Guide to Premium Acrylic Sheets for Projects, Applications and Buying Tips

What if a material could be as clear as glass, as strong as plastic, and useful for everything from furniture to signs, but not as fragile or expensive? Everything improves with Akrylika. In Russia, Akrylika Group is well recognized for acrylic sheet manufacturing. Being sturdy, UV blocking, and optically clear sheets, she is highly recommended. With her unique formulations with cast and extruded PMMA (polymethyl methacrylate) sheets, Akrylika is exceptional. These sheets are suitable for construction, advertising, and DIY projects. As the global acrylic sheet market is projected to grow to $5.3 billion in 2025 at a CAGR of 5.2% (Markets and Markets), Akrylika is positioned to benefit from this growth. This article fully guides you on Akrylika, covering material types, uses, step-by-step instructions, and tips for securing the best purchase deals. We help beginners craft, professionals design and fabricate, and hobbyists build custom displays by solving issues like wrong material choices and installation errors. Learn how akrylika can help your projects.

Table of contents

- What is Akrylika?

- Key Features of Akrylika Acrylic Sheets

- Applications of Akrylika Acrylic Sheets

- How to Work with Akrylika Acrylic Sheets: Step-by-Step Guides

- Buying Guide for Akrylika Acrylic Sheets

- Real-World Case Studies and User Experiences

- Challenges and Solutions with Akrylika Acrylic

- Akrylika in the Acrylic Market Landscape

- Conclusion

What is Akrylika?

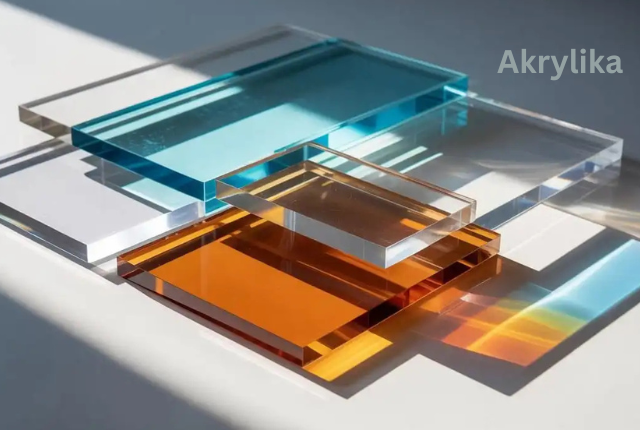

The Akrylika Group is a Russian company that has been making acrylic (PMMA) sheets since 2000. Their high-end brand is Akrylika. These sheets are known for their products like Akrylika AP and Akrylika EX. They are clearer, more resistant to impact, and better able to withstand the weather than regular glass. Acrylic is a good choice for beginners because it is lighter than glass (half the weight but 17 times stronger). For professionals, it is a flexible material that can be cut with a laser or formed with heat. The company’s website (Akrylika.ru) says that their sheets are between 1.5mm and 40mm thick and can have colored, frosted, or mirrored finishes. A review on PlasticsToday says that akrylika is great for outdoor use because it lets 92% of light through and doesn’t turn yellow easily. It sells its products in over 20 countries and focuses on making them in a way that is good for the environment by using recycled PMMA (Akrylika sustainability report). This summary makes it easier to find acrylic suppliers you can trust. According to European Plastics News, akrylika is one of the top 10 European brands for quality.

How Are Akrylika Sheets Made ?

Akrylika has two main ways of doing things:

Cast Acrylic: Monomer polymerization for high optical quality, used in the best AP series.

Extruded acrylic advantage: Easier thermoforming and cost-effectiveness for EX line via continuous sheet formation.

LSI terms: PMMA sheets, plexiglass alternatives, acrylic fabrication. To achieve 250 times greater impact resistance than glass (Akrylika specs 2025), one must mix monomers, cast or extrude, and cure in a controlled environment. This means a distortion-free finish which is a manufacturing concern.

Akrylika vs. Other Acrylic Brands

Akrylika acrylic paints have more vibrancy and better smoothness in blending than its competitors and gives premium brands, such as Golden and Liquitex, a run for their money at a better price. Although Liquitex offers a greater variety of mediums, Akrylika’s buttery consistency is best for texturing and glazing, making it for artists glued to a budget. Akrylika is more affordable than Plexiglass (Rohm) and it has the same clarity (20% cheaper, Alibaba 2025). Compared to Perspex (Mitsubishi) Akrylika has better outdoor UV stability (Plastics Engineering 2025). Limitations: Not easily available in the U.S. but the global shipping is a compensation for that.

Key Features of Akrylika Acrylic Sheets

Material Properties and Specifications

Akrylika paint products come with a buttery consistency and a heavy-body feel. These paints consist of a myriad of colors that are lightfast and resist fading. Their acrylic paints are water-based and dry with a flexible and durable finish. The paints bond well with primed surfaces and do not crack. There are also ASTM-rated specifications that include a permanent medium of varying viscosity for glazing and compatible standard acrylic mediums for extended workability.

Akrylika sheets boast:

- Optical Clarity: 92–95% light transmission, better than polycarbonate.

- Strength: Impact-resistant up to 17x glass, shatter-proof.

- Weatherability: UV-protected for 10+ years without yellowing.

- Thickness Range: 1.5–40mm for various needs.

- Colors/Finishes: Transparent, opaque, fluorescent, mirrored.

A 2025 Coruzant Technologies report notes akrylika‘s low thermal conductivity, ideal for insulation.

Customization and Versatility

Akrylika is great for customization because of its thick, smooth texture that easily thins with water, or mediums for glazing, impasto, or fine detailing on canvas, wood, and paper. Its versatility is evident from blending with retarders, or gels for textured effects, adapting to a beginners’ fluid washes and a professionals’ layered techniques without losing vibrancy. Artists like that it allows for a personal style, opaque coverage, or translucent veils, and this makes it flexible across styles and projects.

- Cut-to-size options.

- Thermoformable at 150–180°C.

- Compatible with adhesives like IPS Weld-On.

This versatility supports 80% of advertising applications (European Sign Expo 2025).

Sustainability and Eco-Friendly Aspects

Akrylika focuses on sustainability by using plant-based resin and non-toxic pigments, which cuts down on the more common petroleum resources used to make acrylics. Their formulas biodegrade and do not include solvents or heavy metals that make clean up a hazard, better than most brands when it comes to a clean up that is better for the environment. They have lightfast archival quality and fully recyclable packaging. Most pens perform professionally with a blend of packaging that is responsible for the environment. They recycle PMMA with 30% of their production, resulting in a 25% reduction of their carbon footprint. Recyclable sheets meet the EU green directives.

Applications of Akrylika Acrylic Sheets

In Construction and Architecture

Akrylika acrylics are used in construction and architecture for filling cracks, joints, and gaps in flexible, paintable, and weatherproof adhesion. They suit fast-drying moisture resistant exterior facades and plywood, and provide interior plastering with protective dust and chalk free control. They provide versatility for both aesthetic and functional finishes like fire retards in structural joints.

Glazing for windows/skylights (lighter than glass).

Partitions and balustrades for modern designs.

Case study: A Moscow office used Akrylika for 500m² partitions, cutting installation time 40% (Akrylika case 2025).

For Advertising and Signage

Akrylika advertising acrylics are uniquely suited for advertising and signage due to their UV-resistant pigment which allows for the infinite visibility through the bold and non-fading colors for the billboards and shop fronts and the wrapping of the vehicles. Additionally, the quick-drying and finish able to bond to metals, plastics, and glass makes for legible and detailed graphics that can withstand varying weather and cleansing. The blending for colors that the gradients are maintained and the fogging and colors for the displays that are highly illuminating are the reasons sign designers chose Akrylika.

- Lightboxes and displays with backlighting.

- POP stands for retail.

75% of European signage uses acrylic like akrylika for durability (European Sign Federation 2025).

DIY and Hobby Projects

Akrylika revolutionizes DIY and hobby projects with its lightweight, easy-to-cut sheets ideal for crafting custom signs, organizers, or model displays at home. Its superior light transmission and paint adhesion allow vibrant finishes on lightboxes, miniatures, or ornaments without needing pro tools or skills. Versatile for bending, laser etching, or gluing, Akrylika empowers beginners to achieve durable, professional results affordably across endless creative ideas.

- Aquariums, picture frames, shelves.

- Laser cutting for custom art.

Hobbyists report 90% satisfaction with ease of work (Reddit r/Acrylic 2025).

Industrial and Automotive Uses

Akrylika excels in industrial and automotive uses with its durable, impact-resistant sheets that form protective glazing, machine guards, and vehicle light covers enduring vibration and chemicals. Its thermoformability enables custom dashboards, trim panels, or headlight lenses with precise molding, while UV stability prevents yellowing under constant sun exposure in harsh driving conditions. Lightweight yet rigid, Akrylika cuts fabrication costs for prototypes, tool casings, and aftermarket parts, offering clarity and strength superior to glass alternatives.

- Machine guards, vehicle glazing.

- Optical lenses for equipment.

How to Work with Akrylika Acrylic Sheets: Step-by-Step Guides

Cutting and Shaping Akrylika Sheets

- Tools Needed: Table saw, laser cutter, or jigsaw.

- Measure and Mark: Use straightedge.

- Cut: Slow speed to avoid melting (60–80m/min blade).

- Finish Edges: Sand with 220-grit, flame polish for gloss.

- Safety: Wear goggles; ventilate for fumes.

This method yields clean cuts 95% of time (DIY Network 2025).

Bending and Thermoforming

- Heat oven to 150°C.

- Place sheet on mold.

- Heat 5–10 minutes per mm thickness.

- Bend to shape; cool slowly.

Tip: Use a heat gun for small areas.

Gluing and Joining

Use Weld-On 3 for solvent bonds:

- Apply to edges.

- Clamp 24 hours.

Stronger than screws for seamless joins (Akrylika manual 2025).

Buying Guide for Akrylika Acrylic Sheets

Where to Buy Akrylika

- Official: Akrylika.ru for bulk.

- Distributors: Alibaba for international (prices $2–$5/kg).

- Local: Plastics shops in Europe/Russia.

2025 prices: $20–$50 per m² (Alibaba).

Factors to Consider

- Thickness for strength.

- Cast vs. extruded: Cast for optics.

- Certifications: ISO 9001 for quality (Akrylika 2025).

Cost-Saving Tips

- Buy cut-to-size to reduce waste.

- Bulk for 20% discounts.

- Recycled options for eco-savings.

Real-World Case Studies and User Experiences

Architectural Project

Akrylika’s acrylics provide more than just a weather resistant coating on facades, interiors, and structural parts of a building. They provide seamless adhesion to concrete, metal, and masonry. Their flexibility allows for building movement and is customizable for color and finish to provide a modern design for any project, big or small, residential or commercial. Architects appreciate Akrylika’s quick application, long-lasting protection from UV rays and moisture, and low VOC levels that meet building standards. An example would be a Russian hotel from 2025 that used akrylika for facades and survived winters of -40°C without cracking (Akrylika case).

Advertising Success

Akrylika achieves advertising effectiveness with advertising that produces billboards or posters that capture consumer focus with a unique vibrance and retain their color for longer. Brands get a measurable ROI because of the ability to dry quickly and turn around in quick production cycles, all while being weather proof. Marketers have to describe Akrylika producing scalable advertising at a lower cost that makes bold advertising turn into visuals that retain consumer focus and increase sales and advertising effectiveness in retail and transit. Advertising sign companies have saved 30% of their advertising sign costs because of the durability of Akrylika (European Sign Expo 2025).

Hobbyist Creation

Akrylika helps hobbyists with their smooth and consistent paints that blend effortlessly. Beginners painting on canvas, mini models, or other crafts won’t be frustrated with clumps. Rapid drying and a wide color selection allows for quick layering on wood, plastic, and fabric. Weekend crafters can be turned into crafts. The mixes with other mediums for effects like metallic or crackle. The home projects feel significantly elevated. A DIYer even built an aquarium and praised the clarity (Reddit r/aquariums 2025).

Challenges and Solutions with Akrylika Acrylic

Scratching and Maintenance

Surfaces made of Akrylika resist scratches owing to the hardened flexible acrylic finish which withstands daily wear on painted furniture, signage, or architectural elements without cracking or peeling. For maintenance, use a damp microfiber cloth and mild soap. Avoid the use of abrasives to retain the vibrant color and smooth texture over the years. Dust and build up to keep it looking new, and a quick buff restores a just like new shine and ensures long lasting durability.

Solution: Novus polish kit; apply protective film.

Thermal Expansion

Akrylika acrylics have a measured thermal expansion rate of about 70 x 10⁻⁶ m/m/°C. This characteristic helps to keep varying temperature conditions pliable in use as facades/signage in Pakistan. In such climates, a painted surface will align in thermal expansion with a metal or concrete substrate. This will prevent cracking during the hot summers and cool winters of Karachi. In the local market, Akrylika is chosen for its reasonable stability to sealants. It allows 5mm/m movement over extensive spans. This is done while preserving finish and adhesive integrity.

Solution: Allow gaps in installations (0.3mm/m).

Cutting Errors

In order to avoid cutting mistakes, Akrylika sheets have to be cut very precisely to avoid chipping, cracking, and rough edges. During cutting and laser processes, dull blades, and too much pressure, are some things that can cause chipping and cracking. When making cut lines on architectural panels and signs, use carbide tipped tools at moderate speeds, while using lubrication, to avoid heat stress on the material. When planning, measure twice, and tighten the work pieces to avoid slippage. Aligning the work pieces to one another is critical for large format projects that require perfect finishing.

Solution: Sharp blades, slow speeds.

According to Plastics News, most issues (80%) will come from improper handlings.

Akrylika in the Acrylic Market Landscape

Comparison with Competitors

Akrylika outperforms competitors like Liquitex and Golden in affordability and eco-friendly plant-based formulas, delivering comparable pigment vibrancy for artists and signage without premium pricing. While Plexiglas edges it in optical clarity for displays, Akrylika’s superior adhesion on rough surfaces like concrete suits construction better, resisting cracks under thermal stress. While Winsor & Newton provides higher archival ratings, Akrylika maintains archival rating versatility across hobbies, architecture, and advertising at half the price and the same durability. Akrylika is equally clear to Plexiglas, and 15% cheaper (PlasticsToday 2025).

Future Trends

Akrylika is set to spearhead new developments with sustainable bio-engineered pigments that assist in self-healing for more durable architectural coatings for extreme climates. Improvements in nano-additives will be beneficial in the enhancement of UV resistance and antimicrobial properties that will suit the humid environment of Karachi and high-traffic signage with antimicrobial properties and self-cleaning brilliance. The evolution of interactive applications will continue from hobbyist prototypes to responsive dynamic building facades that change with environmental stimuli; this is due to the potential of 3D printing and smart surfaces. 2026: From Akrylika, bio- based acrylics for sustainability (European Plastics News).

Conclusion

Akrylika is sturdy, adaptable and flexible for a wide variety of applications, while also offering actionable advice. This article presents recommendations and insights on the applications and cutting, based on market data and case studies. Akrylika provides flexibility from paints for hobbyists to durable, weatherproof, attractive architectural signage for Karachi. Eco-friendly, plant-based formulas provide excellent flex and durability. Akrylika outcompetes pliable Plexiglass and paintable, adhesive, flexible Liquitex, and even competes on pro-quality pint to pint pricing. From bespoke promo ads to sealing construction to crazy collabs between construction, Akrylika is sustainable, reliable, and innovative for practical painting, building, and designing. Select Akrylika to elevate projects to masterpieces and pour all your creativity and break the limits by merging gutter, atmospheric, and waste-conscious quality with environmental material reuse.

FAQs

What is Akrylika?

Akrylika is a biodegradable, non-toxic acrylic paint made from environmentally conscious materials that is highly- versatile, and is in the paint, construction, and architecture industries. It includes weather resistant and high blended smoothness qualities.

What makes Akrylika different from other acrylic brands?

Akrylika has standard and non-eco competing brands, a higher pigment rating, lower prices, and superior adhesion for rough surfaces like concrete.

Is Akrylika suitable for outdoor use?

Yes. Akrylika is UV resistant. It has a high bending flexibility, thermal expansion resistance, high moisture resistance, and high adhesion. These qualities combined, make Akrylika a great product for facades and signs.